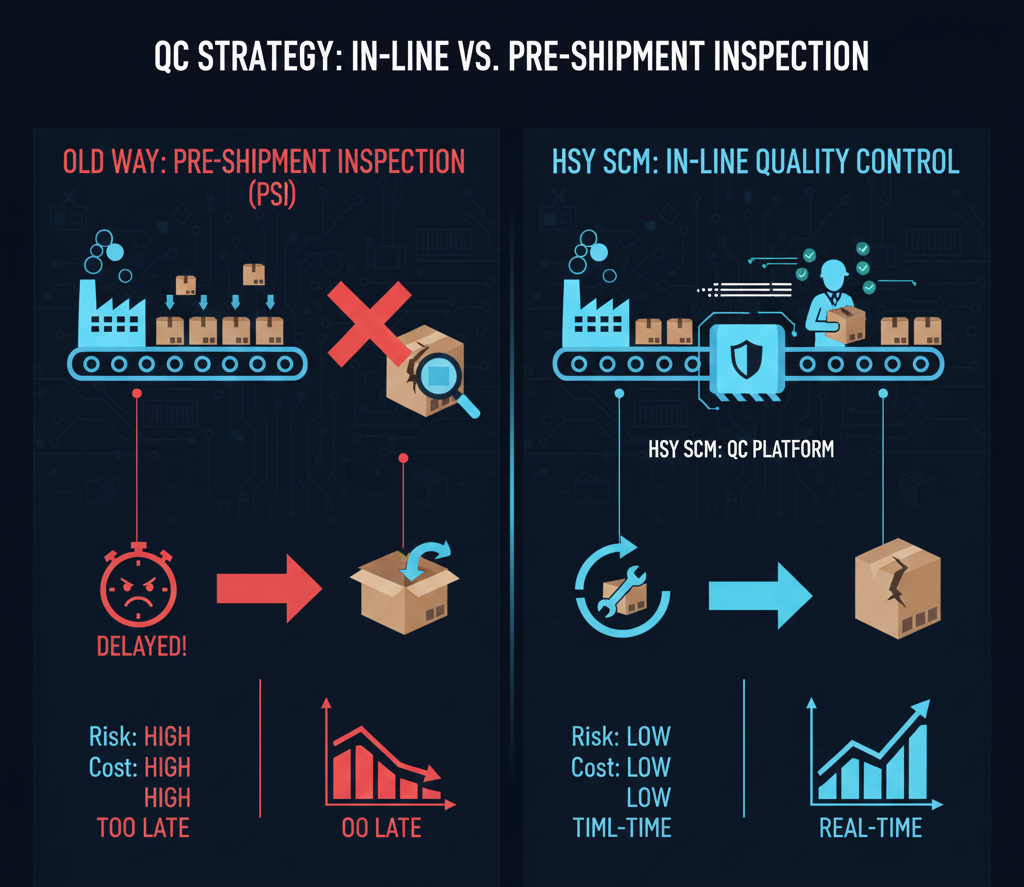

In the world of China sourcing, there is a common, expensive mistake: Waiting until the goods are packed to check the quality.

Most importers rely on the Pre-Shipment Inspection (PSI). But by the time a PSI inspector finds a flaw, your lead time is already ruined. At HSY SCM, we advocate for a more proactive approach.

To build a resilient brand, you need to understand the fundamental shift from detecting errors to preventing them.

1. Pre-Shipment Inspection (PSI): The “Autopsy”

The PSI happens when 80% to 100% of your order is finished and packed. It is a “Pass/Fail” gate.

- The Pro: It’s the final check before you wire the remaining 70% balance. It ensures the quantity and exterior packaging are correct.

- The Critical Flaw: A PSI is an autopsy. If the inspector finds that the internal wiring of your electronics is wrong, or the glaze on your ceramic tiles is the wrong shade, it is too late. The factory has to rework the entire batch, pushing your launch back by 4-6 weeks.

2. In-Line Quality Control: The “Preventative Surgery”

In-Line (or Online) QC happens when only 10% to 20% of your product has come off the assembly line. We go into the factory while the “machines are still running.”

- How it Works: We inspect the raw materials, the first finished units, and the assembly process itself.

- The “First Article” Advantage: If we find that a logo is slightly crooked or a screw isn’t torqued correctly in the first hour of production, the factory adjusts the machines immediately.

- The Result: Zero wasted materials, zero rework time, and a 100% guarantee that the rest of the 2,000 units will be perfect.

3. The Technical Comparison: Which Do You Need?

| Feature | Pre-Shipment Inspection (PSI) | In-Line Quality Control |

| Timing | Production 100% Finished | Production 10-20% Finished |

| Primary Goal | Shipping Confirmation | Defect Prevention |

| Risk Mitigation | Financial (Don’t pay for bad goods) | Schedule (Don’t miss launch dates) |

| Cost of Error | High (Requires full rework/re-production) | Low (Instant adjustment on-site) |

| Recommended For | Simple, repeat commodity orders | Custom designs, complex electronics, new suppliers |

4. Why HSY SCM Recommends the “Hybrid Model”

For high-growth brands, we don’t choose one; we integrate both into a Strategic QC Protocol:

- In-Line Check: We verify the “Golden Sample” against the first batch. We catch the “hidden” issues—internal components, material density, and structural integrity.

- Continuous Monitoring: For large-scale projects (like 10,000+ units), we keep “eyes on the floor” to ensure the factory doesn’t swap materials halfway through the run.

- Final PSI: A quick final check to verify carton labeling, palletizing, and loading for transit.

Lead Time is Your Most Valuable Asset

You can recover money from a factory, but you can never recover a missed Christmas season or a “Sold Out” status on Amazon that kills your ranking.

In-Line QC protects your time. PSI only protects your wallet.

In the competitive landscape of 2026, the brands that win are the ones whose supply chains move without friction. Stop waiting for the autopsy. Start managing the life of your product.

Is your current QC strategy proactive or reactive? Let’s audit your production plan.