The biggest lie in sourcing is that you need $50,000 to start importing from China. You don’t. But you do need a different strategy than the big players.

Factories operate on volume. When you ask for 100 units instead of 10,000, you are disrupting their production line. To succeed in Small Batch Importing, you stop trying to “act big” and start operating smart.

Here is the operational guide to moving small quantities without wiping out your profit margin.

1. Hacking the MOQ (Minimum Order Quantity)

The first wall you hit is the factory saying: “MOQ is 1,000 pieces.”

They aren’t being difficult; they are protecting their setup costs. It costs them the same amount of money to set up the machine for 100 units as it does for 1,000.

The Negotiation Strategy:

Don’t beg. Offer to pay for the inconvenience.

- The “Trial Run” Surcharge: Tell them, “We are testing the market. We will pay a 15% premium on the unit price for a trial order of 200 units.”

- Why this works: It covers their machine setup cost. You pay $5.75 instead of $5.00, but you save thousands in tied-up inventory.

2. Logistics: The “Air vs. Sea” Trap

For small batches (under 200kg or 1 CBM), shipping is where margins die.

- Air Express (DHL/FedEx): Fast (5 days), but destroys profits. Only viable for high-value, small electronics or jewelry.

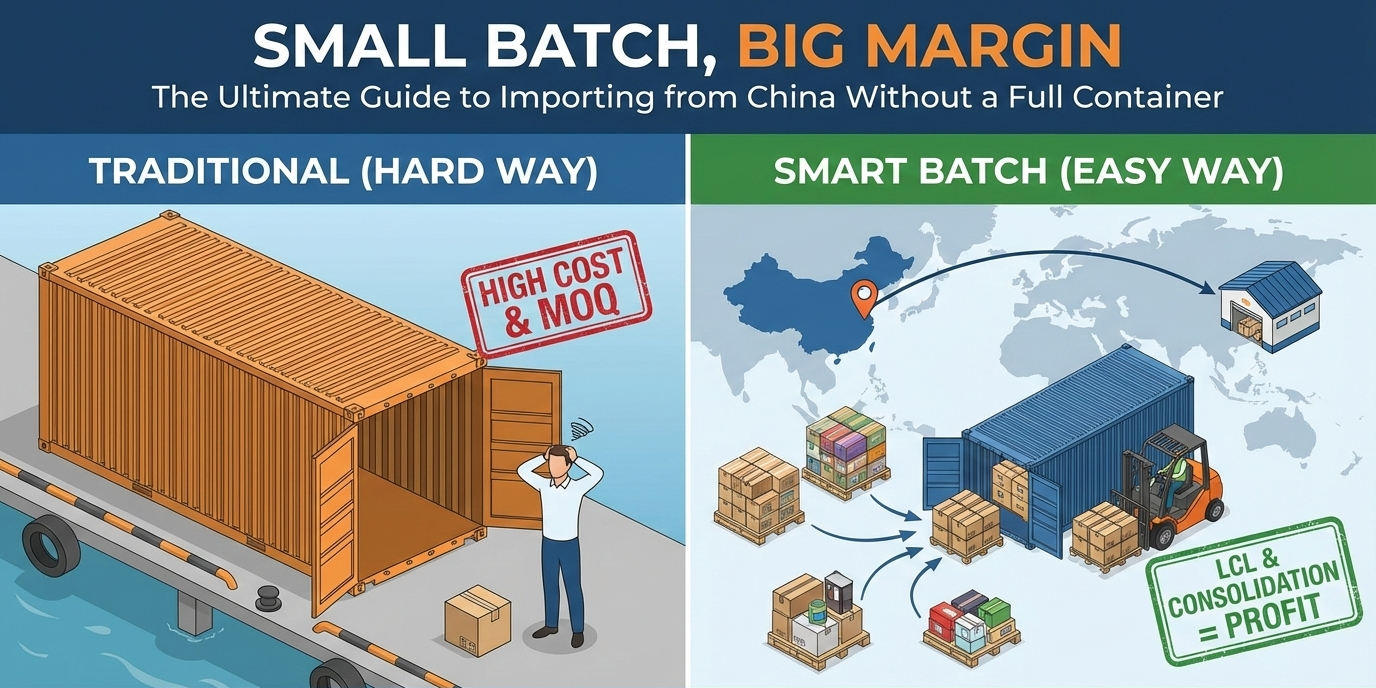

- LCL (Less than Container Load): You rent space in a shared container.

- The Risk: Your goods are palletized with heavy machinery or leaking liquids from other companies. Damage rates are higher.

- The Cost: Forwarders charge high “destination fees” for LCL. A $500 shipping quote can turn into $1,500 after port fees.

3. The Secret Weapon: Cargo Consolidation

This is how smart small businesses compete with big retailers.

Instead of shipping three small boxes from three different suppliers (and paying three minimum shipping fees), you use a Consolidation Hub (like HSY SCM).

The Workflow:

- Buy 300 units of Product A from Supplier X.

- Buy 200 units of Product B from Supplier Y.

- Buy 500 packaging boxes from Supplier Z.

- The Hub: All suppliers ship domestically to our Shenzhen warehouse.

- The Shipment: We combine them into ONE shipment.

| Feature | Direct LCL Shipping | HSY SCM Consolidation |

| Customs Filings | 3 Separate Filings (3x cost) | 1 Filing (1x cost) |

| Shipping Min. Charge | Paid 3 times | Paid 1 time |

| Inspection | None (Blind shipment) | Check upon arrival at Hub |

| Risk | High (Unknown pallet neighbors) | Low (Controlled packing) |

4. Buying “Off the Shelf” (White Label)

If you cannot afford the mold fees for a custom product, stop trying to reinvent the wheel.

The Strategy: Look for factories with “Ready Goods” or “Neutral Stock.”

These are products already sitting in the factory warehouse without a logo.

- The Play: Buy 100 units of neutral stock.

- The Branding: Do not ask the factory to print your logo (their MOQ will be high). instead, source custom packaging or stickers separately and apply them yourself, or have your consolidation agent do it before shipping.

5. Don’t Skip QC Just Because It’s Small

A common mistake: “It’s only a $2,000 order, I’ll risk it.”

If that $2,000 order arrives defective, your business is dead. You have no cash flow to re-order.

For small batches, you don’t need a full audit. You need a basic check. Ask your sourcing partner to open 10% of the boxes, check the color, plug it in, and weigh it. Never ship blind.

Conclusion: Agility is Your Advantage

Big corporations move slowly. You can move fast.

By using consolidation and negotiating smart trial orders, you can test new products every month without risking your life savings.