If your brand is scaling 2x or 3x year-over-year, your biggest risk isn’t your marketing spend—it’s your supply chain breaking. Most sellers start by picking a “winner” from a factory catalog. But at the high-growth stage, that model becomes a liability.

To protect your margins and your brand’s exit value, you have to move from “buying products” to “managing a system.”

At HSY SCM, we help brands bridge this gap. Here are the three advanced strategies that separate 8-figure brands from the rest.

1. From RFQ to BOM Management

Beginners send an RFQ (Request for Quote) for a finished product. Advanced brands manage the BOM (Bill of Materials).

When you control the BOM, you know exactly what goes into your product. You don’t just ask for a “faucet”; you specify the H59 Brass content, the brand of the ceramic cartridge (e.g., Sedal), and the microns of the PVD coating.

- The Advantage: You stop paying the “convenience markup” that factories add when they source sub-components for you.

- The Moat: If a factory tries to raise prices, you own the specs for every screw and seal. You can move production because you own the technical “recipe.”

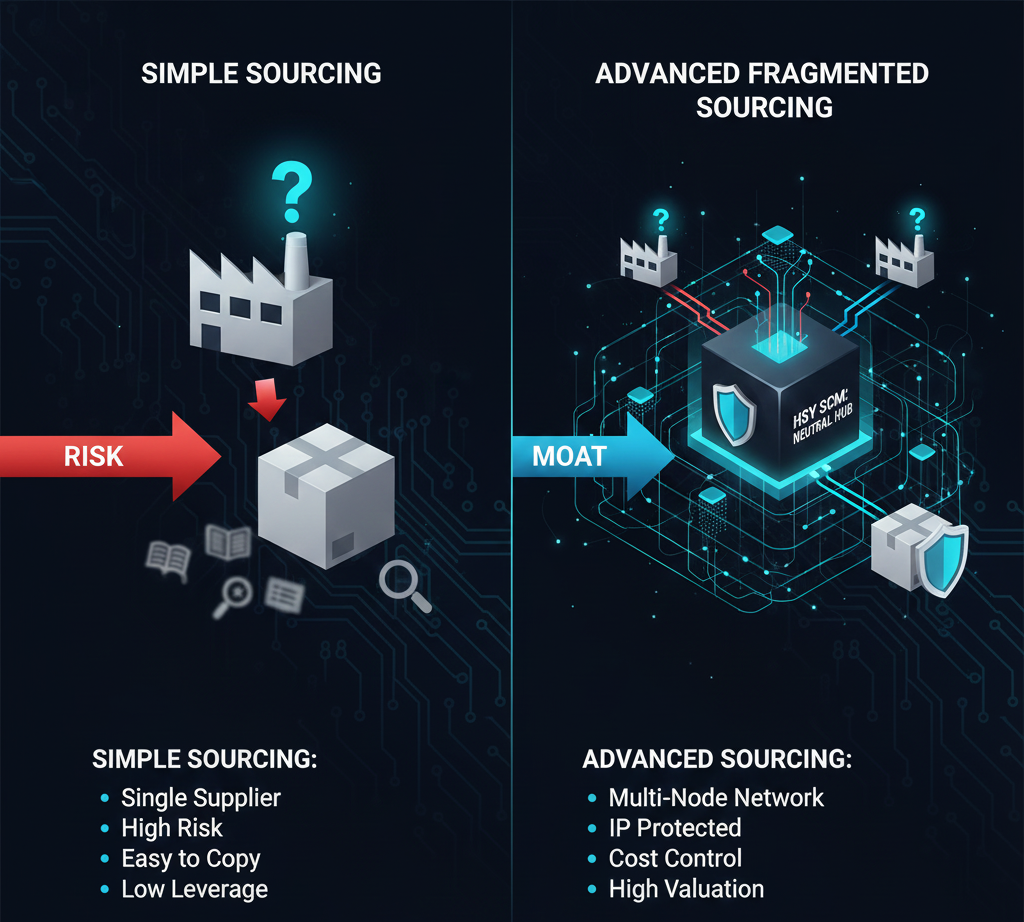

2. The “Multi-Node” Fragmented Strategy

High-growth brands cannot afford a single point of failure. If your only factory gets hit with an environmental audit or a power crunch, your business stops.

Advanced Strategy: Split your production.

- Component Nodes: Source the core engine/parts from Factory A and the aesthetic housing from Factory B.

- The Neutral Hub: Ship all components to a neutral facility like HSY SCM. We handle the final assembly, kitting, and QC.

| Feature | Simple Sourcing (Alibaba Style) | Advanced Fragmented Sourcing |

| IP Protection | Low (Factory sees everything) | High (No one factory has the full design) |

| Pricing Leverage | Low (Take it or leave it) | High (You negotiate at the component level) |

| Supply Security | Risky (Single source) | Resilient (Diversified nodes) |

3. Real-Time “In-Line” Quality Control

Waiting for a “Pre-Shipment Inspection” (PSI) is a amateur move. By the time a PSI finds a defect, your lead time is already ruined.

Advanced sourcing involves In-Line Inspections. At HSY SCM, we go to the factory while the goods are still on the line.

- The “First Article” Check: We verify the first 50 units off the line against your CAD drawings.

- Material Lab Testing: We don’t take the factory’s word for it. We use spectrometers to verify stainless steel grades and chemical tests to ensure lead-free compliance.

4. Engineering for Logistics

High growth requires aggressive cash flow management. If you are shipping air, you are losing money.

We work with our brands to redesign packaging for container density. * Example: Modifying the leg of a wardrobe so it can be flat-packed more efficiently.

- The Result: Increasing container capacity from 200 units to 250 units. That 25% increase in shipping efficiency goes straight to your net profit.

The HSY SCM Advantage: Your Ground Team in China

High-growth brands need more than an “agent”—they need a Supply Chain Architect.

We provide the infrastructure for you to execute these advanced strategies without needing a 20-person team in Shenzhen. We handle the technical audits, the BOM breakdown, and the high-stakes negotiations that happen on the factory floor, not over email.