A perfect seal is the final guard for your product’s quality. We help global B2B buyers and brand owners source reliable sealing solutions—from vacuum and induction to continuous band sealers. We focus on temperature precision, mechanical durability, and seamless integration into your packing line.

Why Precision Sourcing is Critical for Sealing Equipment

For high-volume importers, a low-cost sealing machine often hides operational risks that can lead to product spoilage or recalls:

- Inconsistent Temperature Control: Poor-quality heating elements lead to “cold spots” or overheating, resulting in weak seals or burnt packaging.

- Material Incompatibility: A machine that works for PE may fail with thick laminated bags or bio-plastics. We verify the machine’s performance with your specific packaging film.

- Vacuum Integrity: In vacuum sealers, the quality of the pump determines the ultimate shelf life. We audit the pump’s brand and suction capacity.

- Electrical Safety: Many entry-level machines lack proper shielding or CE-compliant wiring, posing risks in professional factory environments.

HSY Sourcing mitigates these risks by conducting real-load testing with your samples before shipping.

Specialized Sealing Solutions We Manage

We identify and verify manufacturers in China’s packaging machinery hubs (Zhejiang and Guangdong):

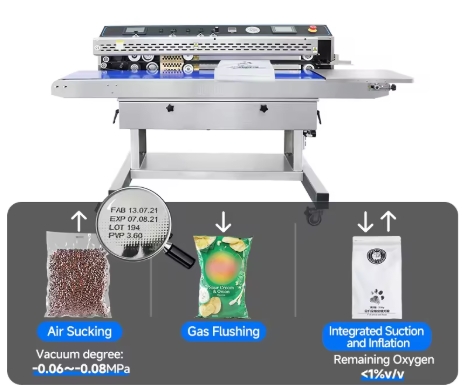

- Continuous Band Sealers: High-speed horizontal and vertical sealers for pouches and bags.

- Induction Cap Sealers: Non-contact electromagnetic sealing for bottles in food, pharma, and chemical industries.

- Vacuum & Gas Flush Sealers: For extending shelf life in food and electronics packaging.

- Tray & Cup Sealers: Precision equipment for the catering and ready-meal industries.

- Pneumatic & Impulse Sealers: Heavy-duty solutions for large industrial bags and liners.

Our Performance-Focused Inspection Protocol

We don’t just check the exterior finish. We audit the mechanical soul of the machine:

- Thermal Stability Test: We use digital thermometers to verify that the heating bar maintains a consistent temperature across its entire length during continuous operation.

- Pressure & Leakage Test: We perform “squeeze tests” or bubble tests on sealed samples to ensure 100% airtight integrity.

- Component Brand Verification: We check the PLC, sensors, and motors to ensure they match the agreed-upon technical specs (e.g., Schneider, Omron, or high-quality domestic brands).

- Speed & Throughput Validation: Verifying that the machine hits the target “cycles per minute” without compromising seal quality.

- Safety Guard Audit: Ensuring all moving parts and heating zones are properly shielded for operator safety.

Partner with HSY Sourcing: Seal Your Success

The packaging industry is moving toward sustainable materials and higher automation. HSY Sourcing helps you navigate these shifts in the Chinese market.

With deep roots in the machinery manufacturing heartlands, HSY Sourcing connects you with reliable Sealing Machine manufacturers who prioritize precision and compliance. We manage the technical specs, factory audits, and pre-shipment inspections. We simplify your procurement, giving you clearer control over equipment reliability and production uptime.

FAQ

Q: Can you help us test the machine with our own packaging bags?

A: Absolutely. We always recommend sending samples of your specific bags/containers to the factory. We will supervise the testing process and send you high-definition video of the seal quality.

Q: How do you handle voltage and plug requirements for our country?

A: This is part of our basic audit. We ensure the motor and heating system are customized for your local power standards (e.g., 110V/60Hz or 220V/50Hz).

Q: What about wear-and-tear parts like Teflon belts?

A: We negotiate with the factory to include a “First-Year Maintenance Kit” (heating wires, Teflon tapes, fuses) with every shipment to minimize your downtime.