Success in the baking market starts with reliable tools. We help B2B importers source high-performance bakeware, silicone molds, and pastry tools from verified manufacturers. From material safety audits to heat-distribution testing, we ensure your products meet the highest standards of professional and home bakers alike.

Navigating the Compliance-Heavy Bakeware Supply Chain

For professional brands, a single compliance failure can lead to massive recalls. When sourcing bakery tools in China, the real challenges are:

- Non-Stick Coating Integrity: Are the coatings truly PFOA-free? We verify if factories use reputable brands like Whitford, ILAG, or Greblon to ensure longevity and safety.

- Material Gauge & Durability: Carbon steel that is too thin will warp in high temperatures. We ensure the steel gauge (thickness) matches the technical specifications for even heating.

- Silicone Quality: Preventing “fillers” in silicone products. We perform the “twist test” and verify LFGB/FDA food-grade certification.

- Rust & Corrosion: Poorly rolled edges on carbon steel pans often lead to rust after the first wash.

HSY Sourcing monitors these production details to ensure your brand stands for quality and safety.

Professional Bakery Solutions We Source

We match your project with specialized manufacturing clusters in Guangdong and Zhejiang:

- Metal Bakeware: Non-stick cake pans, cookie sheets, muffin tins, and loaf pans (Carbon Steel / Aluminized Steel).

- Silicone Molds: BPA-free, platinum-grade silicone for baking, chocolate, and candy making.

- Pastry & Decorating Tools: Stainless steel piping tips, spatulas, rolling pins, and flour sifters.

- Measuring & Prep Tools: Accurate measuring cups, spoons, and professional mixing bowls.

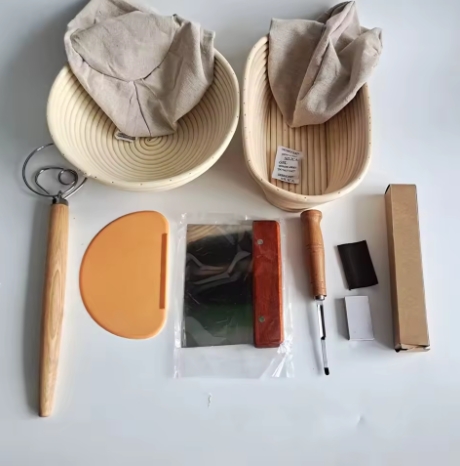

- Pizza & Specialty Tools: Pizza stones, cutters, and professional-grade proofing baskets.

Our Comprehensive Bakeware QC Protocol

We don’t just count the cartons. We test the functionality:

- Coating Adhesion & Release Test: We supervise the “Dry Egg” or “Grid Cut” tests to ensure the non-stick coating is durable and performs as promised.

- Dimensional Tolerance: Checking the precise fit of removable bottoms and the uniformity of pan depths.

- High-Temperature Stability: Testing silicone and metal tools in commercial ovens to ensure no deformation or chemical odors at 230°C+ (450°F+).

- Food Contact Verification: Checking factory certifications for FDA, LFGB, and REACH to ensure legal entry into the US and EU markets.

- Edge & Rivet Inspection: Ensuring all rolled edges are smooth and rivets are secure for long-term safety.

Partner with HSY Sourcing: Elevate Your Bakery Brand

The global bakery market is evolving toward eco-friendly packaging and ergonomic designs. HSY Sourcing helps you capture these opportunities with transparency and expertise.

With deep roots in China’s kitchenware hubs, HSY Sourcing connects you with reliable Bakery Tool manufacturers who prioritize innovation and compliance. We manage the sampling, factory audits, and final loading inspections. We simplify your procurement, giving you clearer control over product safety, material costs, and lead times.

FAQ

Q: Can you help us customize colors for silicone tools (Pantone Matching)?

A: Yes. We can match silicone materials to any Pantone color and manage the sampling process to ensure color consistency across the entire product line.

Q: How do you verify if a factory is truly using branded coatings?

A: We verify the factory’s purchasing records and invoices from coating suppliers and can arrange for the supplier to provide a direct Certificate of Authenticity for your order.

Q: What is the typical MOQ for custom-engraved baking pans?

A: For standard shapes with a custom logo, the MOQ is usually 1,000–3,000 pieces. For completely custom shapes requiring new tooling, we can negotiate the development costs and MOQs on your behalf.