Setting up or upgrading a cookware factory requires more than just machines—it requires a seamless integration of technology and workflow. We help global manufacturers source complete production lines for Stainless Steel and Aluminum cookware. From deep-drawing to non-stick coating systems, we ensure your line is engineered for efficiency and high-yield output.

Navigating the Technical Risks of Production Line Procurement

Buying a manufacturing line is a high-stakes investment. In the China supply chain, B2B buyers often face integration gaps:

- Mismatched Cycles: One machine runs faster than the next, creating bottlenecks that reduce the overall factory OEE (Overall Equipment Effectiveness).

- The “Assembled” Risk: Sourcing separate machines from different vendors without a master integrator often leads to wiring and software compatibility issues on-site.

- Coating Consistency: For non-stick lines, the curing oven’s temperature stability is the difference between a premium pan and a batch of defects.

- Missing Technical Documentation: Receiving a line without clear English manuals or electrical diagrams makes local maintenance impossible.

HSY Sourcing bridges these gaps by auditing the entire workflow and supervising the “dry run” of the integrated line before disassembly and shipping.

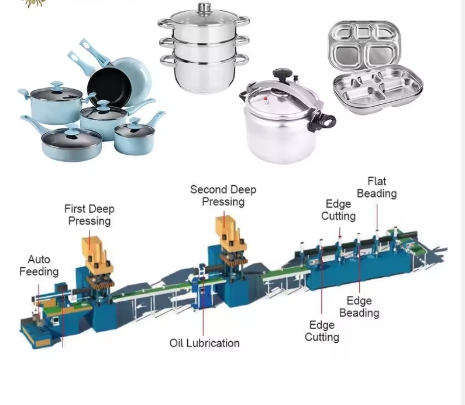

End-to-End Cookware Production Technology

We source equipment for every stage of the cookware manufacturing process:

- Cutting & Circular Blanking: High-speed hydraulic presses and automatic circle cutting machines for steel and aluminum discs.

- Deep Drawing & Forming: Heavy-duty hydraulic presses with precision molds for pot and pan bodies.

- Impact Bonding & Brazing: Automated bottom-bonding machines for induction-ready multi-ply bases.

- Surface Treatment Lines: Professional polishing, sandblasting, and multi-stage non-stick coating (spraying/roller) lines.

- Trimming & Beading: Automatic edge-cutting and rolling machines for consistent rim quality.

- Assembly & Packaging: Handle riveting, laser marking, and final cleaning/packing conveyors.

Our Turn-key Project Oversight Protocol

We treat a production line as a single organism. Our QC process includes:

- Workflow Simulation: We verify the production capacity (e.g., 500 units per hour) by supervising a full-cycle test run at the vendor’s facility.

- Safety & Electrical Audit: Checking the brands of sensors, PLC controllers, and emergency stop systems to ensure they meet your local industrial standards (CE/UL-ready).

- Mold & Tooling Validation: Inspecting the precision of the molds to ensure the output products match your 3D designs exactly.

- Disassembly & Logistics Marking: Supervising the labeling of every wire and pipe during disassembly to ensure your local team can reassemble the line quickly.

- Commissioning Supervision: Negotiating for the factory’s engineers to provide on-site installation and staff training in your country.

Partner with HSY Sourcing: Build Your Factory with Confidence

The cookware industry is moving toward high automation and energy-saving induction technology. HSY Sourcing helps you stay ahead by connecting you with China’s most reliable machinery integrators.

With deep roots in the manufacturing hubs of Guangdong and Zhejiang, we manage the technical communication, vendor vetting, and pre-shipment inspections. We simplify the complex process of sourcing a manufacturing line, giving you clearer control over project timelines, technical specs, and your long-term ROI.

FAQ

Q: Can you help us source a semi-automatic line to reduce labor costs?

A: Yes. We can help you find a balance between manual and automatic stations (e.g., automated deep drawing with manual polishing) to fit your budget and local labor conditions.

Q: How do you handle the after-sales and spare parts for large lines?

A: We ensure the contract includes a 2-year “Critical Spare Parts Kit” and verify the factory’s capability to provide remote PLC troubleshooting via the internet.

Q: Do you help with the factory layout design?

A: We coordinate with the equipment engineers to provide the machine footprint and power/water requirements so your facility is ready before the containers arrive.